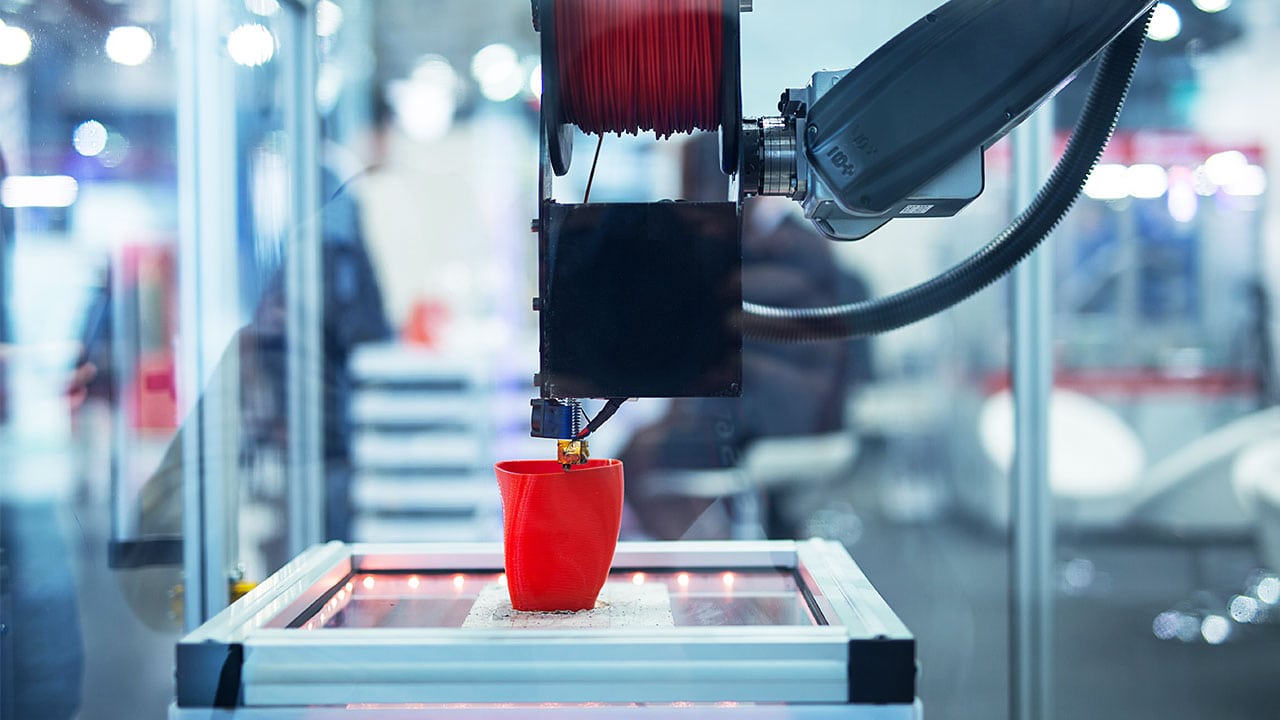

3D printing refers to the process of printing three-dimensional solid objects from a digital file. Once a virtual design of an object has been created using a CAD modeling program, the software slices the model into hundreds of horizontal layers. This file is then uploaded to the 3D printer and the printer creates the physical object layer by layer.

While 3D printing technology has the potential to revolutionize so many of today’s industries, it does have certain drawbacks as well. One of its most significant disadvantages is the amount of time that the printing process takes, which can be several hours, to several days depending on the product size. To combat this issue, a new company called Carbon 3D has recently developed a newer, faster 3D printing process.

If you plan to pursue CAD training, this is one method of printing that you’ll want to keep tabs on—you might even be using it once you’ve earned your diploma! Read on to find out more.

Carbon 3D Unveils A New Printing Process

Standard 3D printing allows objects to be printed in the air, then cured under UV light. Since a lot of oxygen is present during this process, it is generally very slow. However, a new development in 3D printing by tech company Carbon 3D, allows objects to be printed continuously using a liquid interface in one single step, as opposed to multiple processes.

Carbon 3D’s new printer works by projecting a sequence of UV images through the bottom of an oxygen-accessible, UV transparent window. This window is located directly beneath a liquid resin bath, which is made up of chemical reactants. The printer is able to control when and how much oxygen is permitted to enter the resin pool. In turn, the oxygen is able to create a “dead zone” within the resin bath, where it is impossible for photopolymerization to take place. The printer then produces a series of cross-sectional images using UV light.

How Fast Does This Machine Actually Print?

Recent tests proved that a structure measuring approximately 5cm in height was able to print in less than 10 minutes. While it’s not the speed we’re used to in today’s digital age, students enrolled in CAD courses know that compared to the hours it typically takes a standard 3D printer, this time is very impressive. What makes this 3D printing process so much faster than any other method, is its ability to continuously work on creating an object instead of doing so layer upon layer. In fact, this new process is only really limited by resin cure rates.

Do you think that this method of 3D printing will become standard by the time you earn your CAD diploma?