Why and How: The Benefits of Meeting with a Digital School Admissions Advisor

Why and How: The Benefits of Meeting with a Digital School Admissions Advisor

The Benefits of a BIM Technician Certificate

The Benefits of a BIM Technician Certificate

Unlocking Your Potential: The Benefits of a Diploma from Digital School Technical Design College

Unlocking Your Potential: The Benefits of a Diploma from Digital School Technical Design College

April Newsletter: What’s New with Digital School?

April Newsletter: What’s New with Digital School?

February Newsletter: What’s New with Digital School?

February Newsletter: What’s New with Digital School?

In-Demand Skills for AEC Professionals

In-Demand Skills for AEC Professionals

December Newsletter: What’s New with Digital School?

December Newsletter: What’s New with Digital School?

Unlocking Career Success: The Power of Online Technical Design Colleges

Unlocking Career Success: The Power of Online Technical Design Colleges

May Newsletter: What’s New with Digital School?

May Newsletter: What’s New with Digital School?

Canada Eliminates Interest on Student Loans

Canada Eliminates Interest on Student Loans

March Newsletter. What’s New with Digital School?

March Newsletter. What’s New with Digital School?

Sustainable Design in the Modern AEC Industry

Sustainable Design in the Modern AEC Industry

Digital School Welcomes New Nation-Wide Funding Options

Digital School Welcomes New Nation-Wide Funding Options

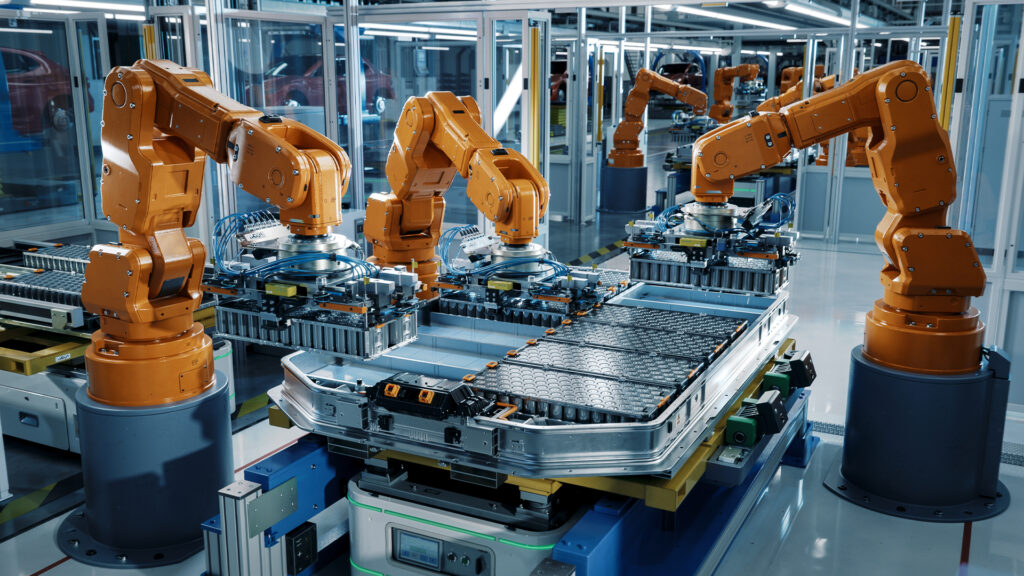

Computer Aided Design Applications in Manufacturing

Computer Aided Design Applications in Manufacturing

Digital School Announces Limited-Time, Guaranteed Scholarship

Digital School Announces Limited-Time, Guaranteed Scholarship

November Newsletter. What’s New with Digital School?

November Newsletter. What’s New with Digital School?

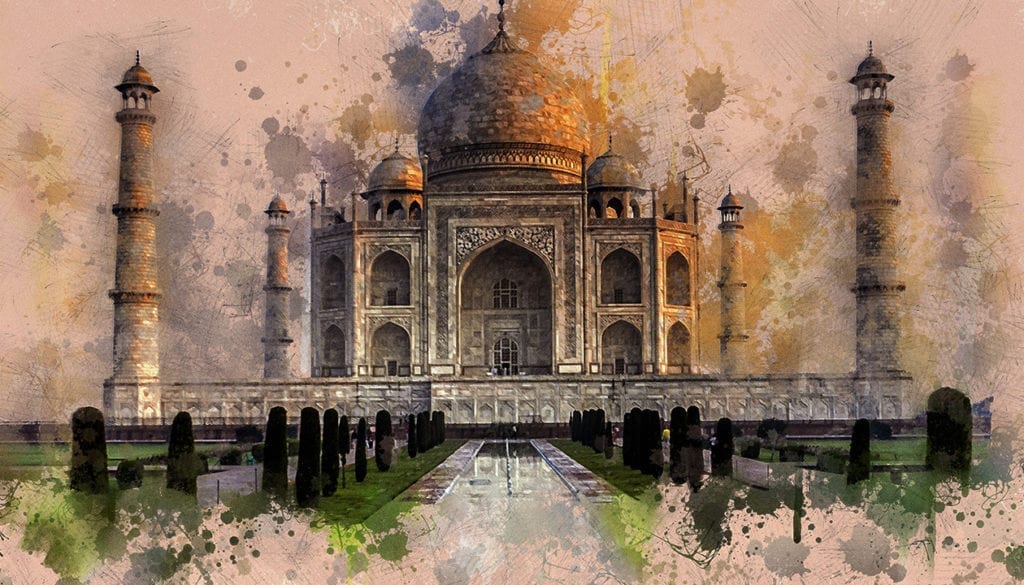

These 4 Buildings Will Inspire You in Technical Design

These 4 Buildings Will Inspire You in Technical Design

3 Areas to Explore in Your Architectural Design Training